Mine

Planning

Software

Our mining engineering products provide a suite of design, scheduling, optimisation and execution solutions that cover multiple planning horizons from strategic planning through to operations.

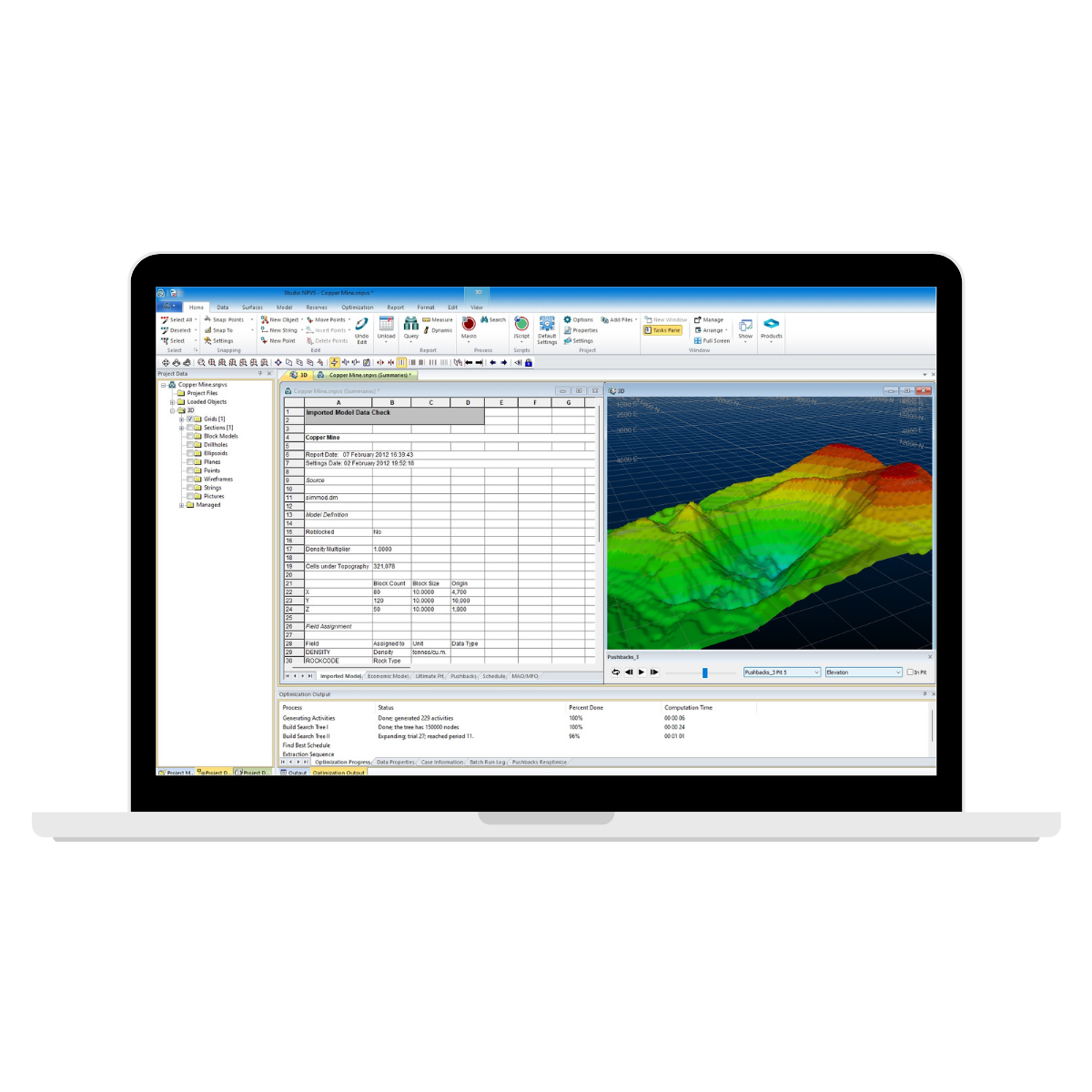

Complete strategic open pit mine planning system

The physical design and production schedule of a mine are inextricably linked. Studio NPVS is unique in the mining industry as the only strategic mine planning system that optimises both of these elements in the search for maximum NPV. As a complete strategic open pit mine planning system – Studio NPVS has functionality spanning data preparation, pit optimisation, pushback generation, cut-off grade optimisation, scheduling, haulage analysis and stockpile management. In addition, the Studio NPVS family of products have the full power of a general mining package delivered by Datamine Studio’s core platform. The advanced system caters for alternative techniques beyond NPV for pit optimisation to take account of material blending requirements, or to maximise mine life. The innovative pushback generator delivers the most practical pushbacks of any competing product and the scheduling capability includes optimisation techniques that look ahead to the entire life of the mine as opposed to considering just one period at a time.

Sophisticated scheduling, blending, stockpiling, grade optimisation, process optimisation, production targeting and haulage optimisation.

Easy-to-use methodology with multiple layers of sophistication, from quick studies to detailed mine plans.

Ultimate pits are optimised for maximum cash flow, maximum reserve life and maximum NPV.

Minemax

Strategic & Operational

Mine Planning Software

Designed for mining people, by mining people

Minemax Scheduler

Best-in-class mine schedule optimization software

Minemax Scheduler is a best-in-class mine schedule optimization software that jointly optimizes mine schedules and associated mining, processing and transport infrastructure to deliver optimal strategic mine plans that meet all project constraints. With Minemax Scheduler, you can model all aspects of your mine schedule at once, including trucking, waste dump sequence, cut-off and cut-over grades, material destinations, leach processing, and CAPEX to achieve maximum value for your business.

Leverage the power of Scheduler's flexible scheduling engine to model key strategic decisions.

Integrate your mine schedule and waste dumping or time-delayed leach processing

Simultaneously optimize mine schedules with multiple capex decisions

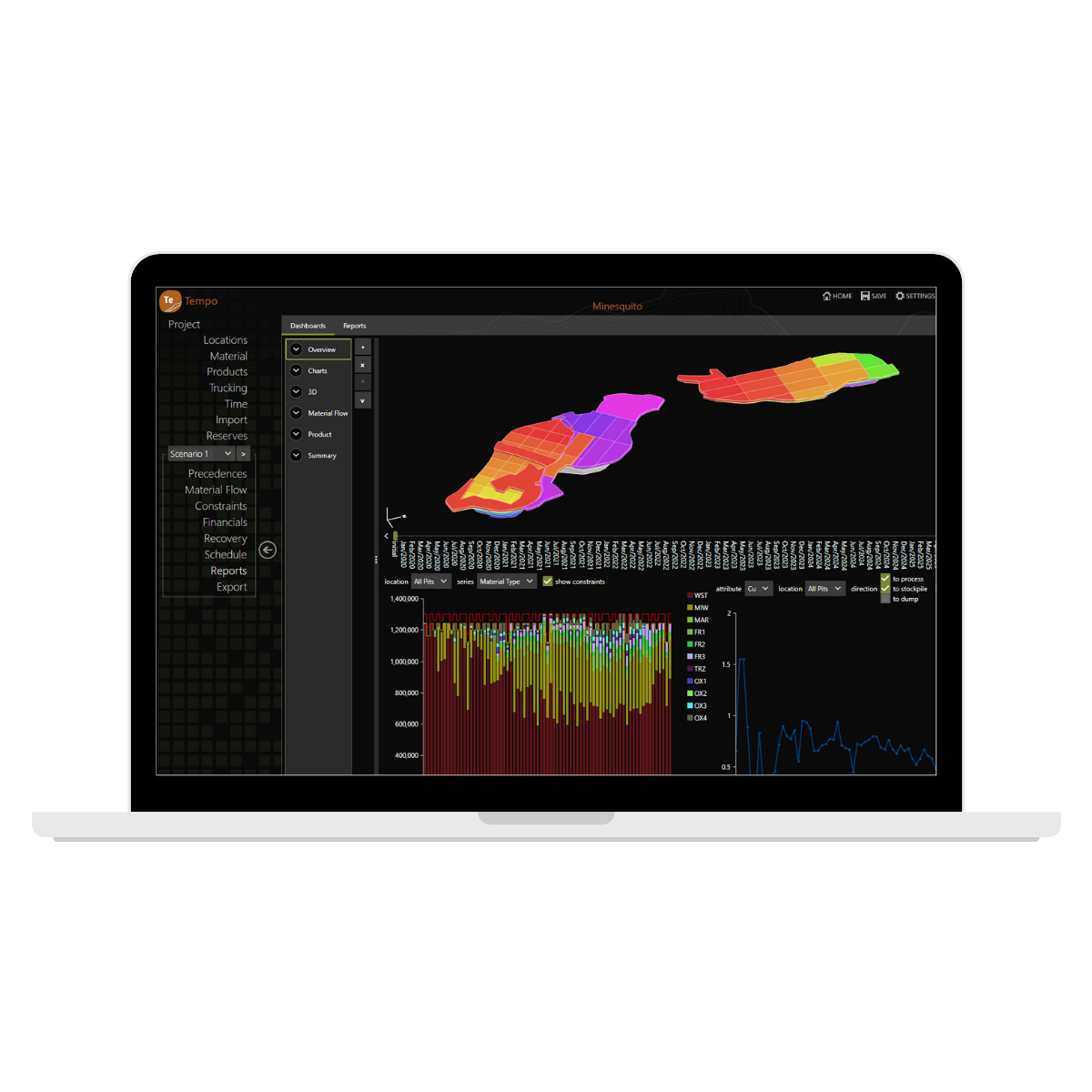

Minemax Tempo

Generate detailed plans to follow your strategic plan.

Tempo is an easy-to-use solution to quickly develop practical open pit mine schedules that satisfy mining, processing and trucking constraints and that align with strategic plans. Tempo‘s intuitive workflow make the schedule setup simple and straightforward. With its choice of powerful scheduling engines, Tempo is a highly functional tool for detailed mine planning that addresses real challenges facing mine planners in their operations. To create a detailed schedule in Tempo, mine planners can bring in polygons, regularized block models or translate blocks into bench polygons. They can also use outputs from strategic scheduling software like Minemax Scheduler to guide their detailed planning.

Easy to use interactive user interface with an intuitive workflow that guides mine planners through the schedule setup.

A choice of powerful scheduling engines including Minemax industry proven optimisation technology to deliver maximum value outcomes.

Flexible and concise dashboards allow users to quickly analyse schedule KPIs or export results for project implementation

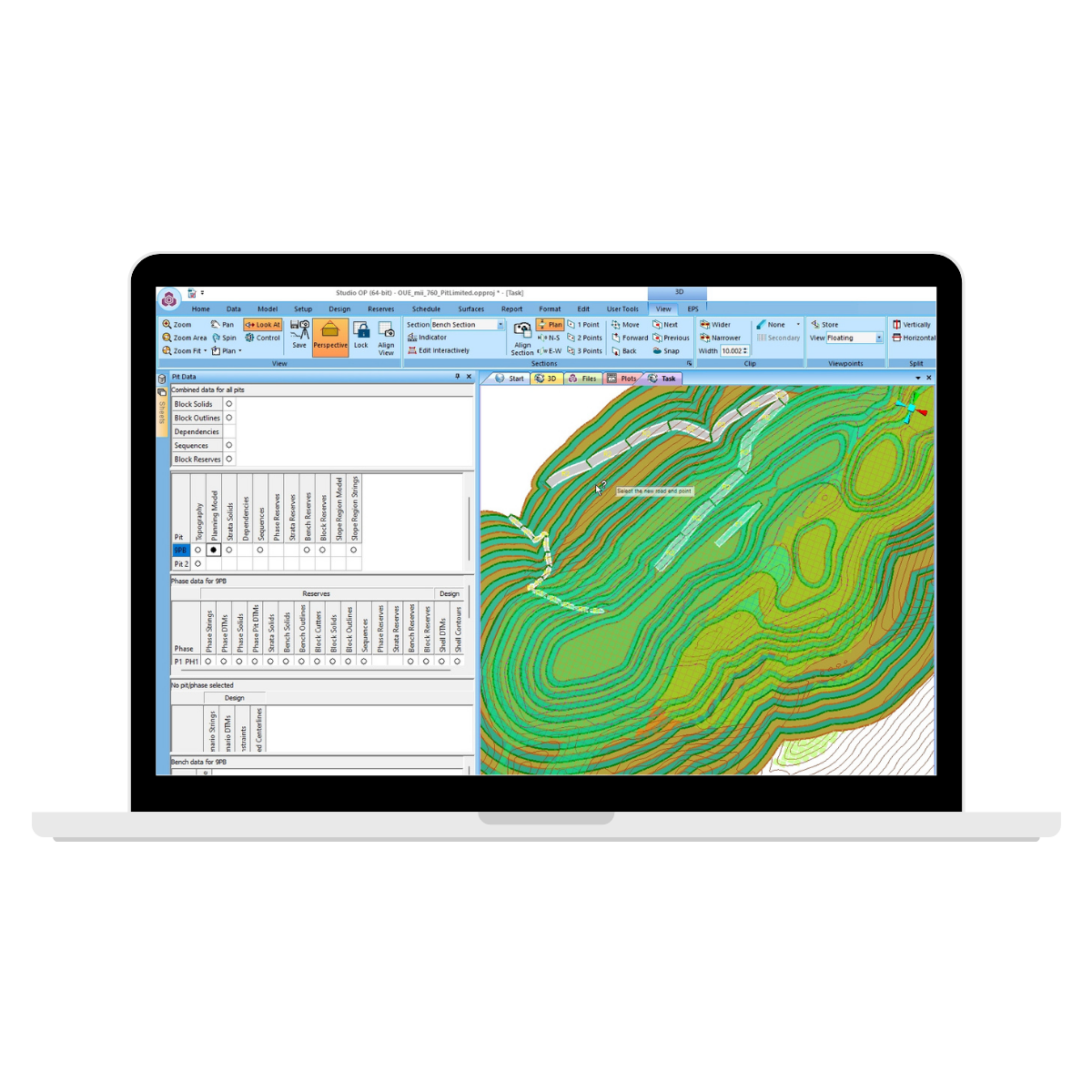

Superior open pit design & scheduling system

Studio OP is a complete design and scheduling product for short– and medium-term planning of open pit mines. Packed with functionality for automated reserve generation, pit design and scheduling, Studio OP makes generating and comparing alternative mine plans a breeze. Studio OP uses sophisticated algorithms and data management throughout. Its innovative rules-based automated design sets a new standard for designing open pits and dramatically increases the number of alternative designs and layouts that can be considered. When it comes to scheduling with minimal manual intervention, Studio OP’s Auto Scheduler can be used to produce practically achievable schedules with desired financial outcomes, product blend specifications and realistic equipment movement. Schedules can be optionally exported to EPS for communication, reporting or further manipulation with its intuitive Gantt chart interface. Whether you have responsibility for producing medium-term plans and budgets or detailed short term operational schedules, Studio OP can help achieve the best possible outcomes for your organisation.

Fast and smart automated design of open pits – interactively edit rules within seconds.

Automatically generate detailed mining blocks and reserves from strategic mine plans.

Smart mix of industry standard and proprietary optimisation algorithms for automatically obtaining practical schedules.

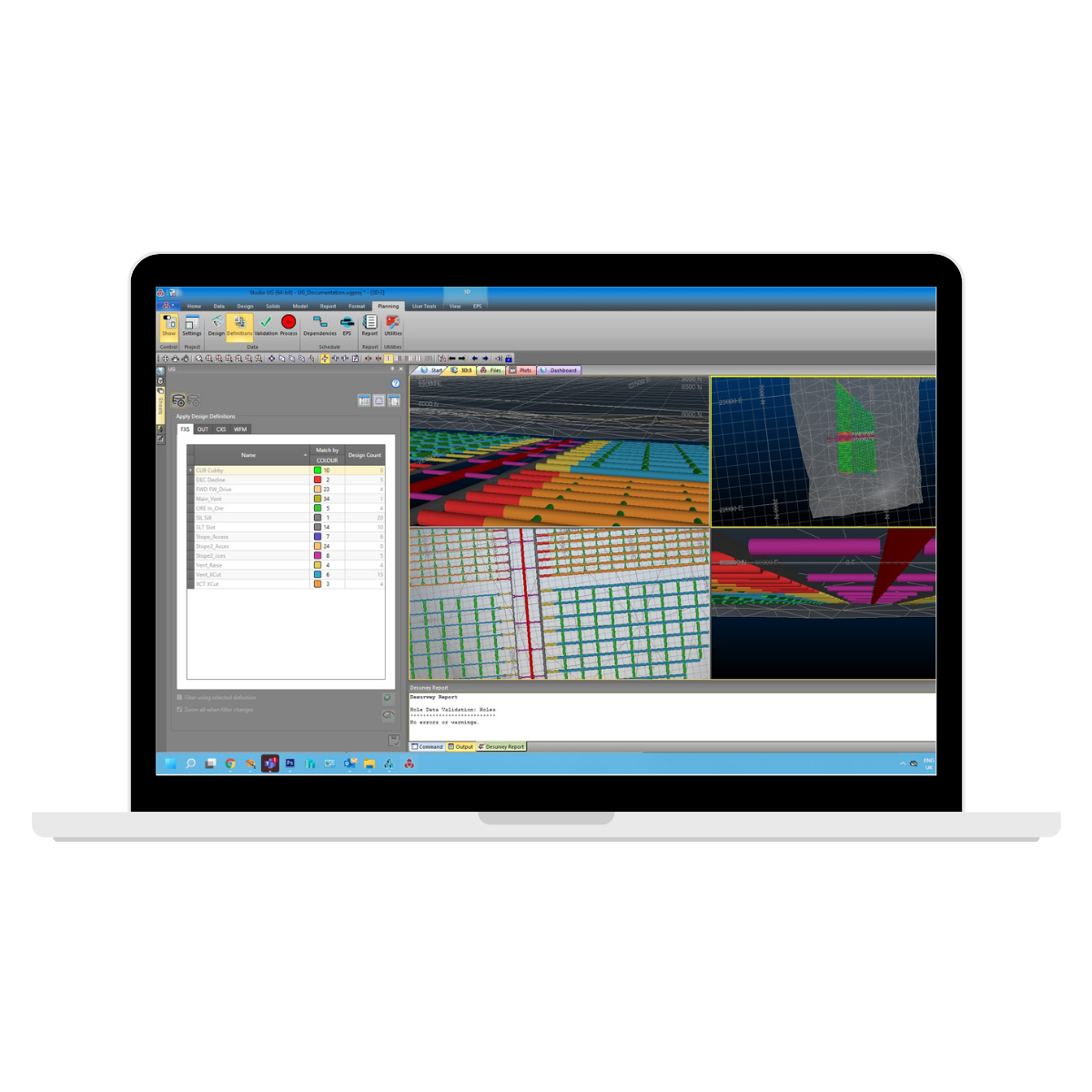

Design, schedule & optimisation

Leading the way for integrated underground design and scheduling – Studio UG is the comprehensive toolkit that has a unique, single-step process to generate all scheduled activities from source data in seconds. Data preparation is completely automated to achieve an extremely efficient and robust system for delivering underground design data to your scheduling environment. Mine standards are incorporated in templates, saving you time, whilst multiple users can work on portions of the mine simultaneously, eliminating the potential for doubling up of work or unnecessary redundancies. It can robustly handle larger datasets, multiple synchronised views and full block model display including slices, blocks and point cloud representations. Data processing can now be completed in one step as Studio UG processes all the data types with a single click. New sequence rules created using attributes deliver an additional method to generate sequence links, and the integrated scheduling features mean a schedule can be rapidly updated with design changes without any loss of previous manual interventions within the schedule.

Easily and quickly produce and compare multiple alternative stope designs and arrangements to save you valuable time and resources.

Automated processes that efficiently eliminate repetitive tasks, giving you more time in the day.

Easily capture and automate pieces of workflow with Studio UG‘s scripting and customisation capabilities.

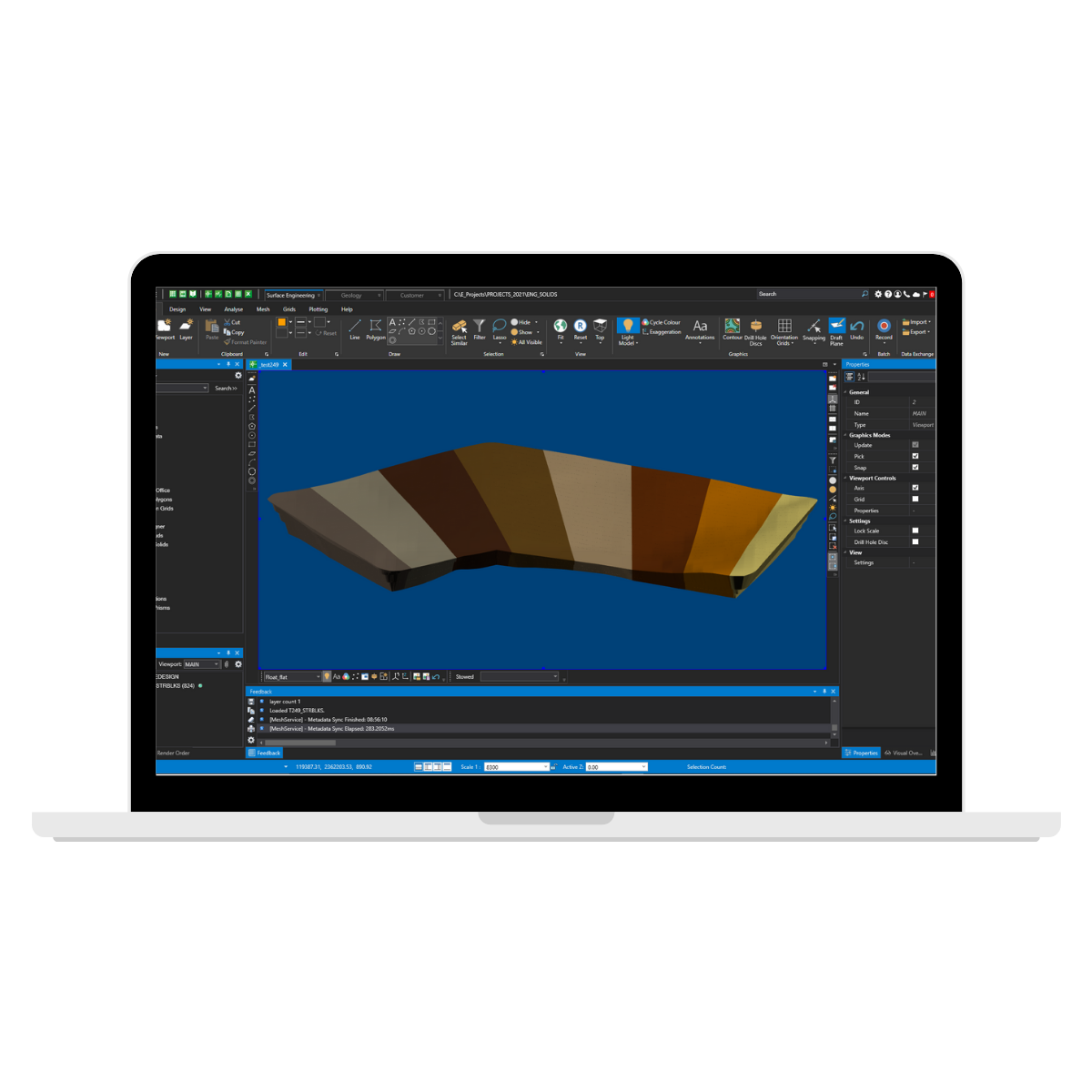

Rapid, intuitive, efficient

MineScape Surface Engineering is a suite of solutions designed for open-cut mining operations for coal and metalliferous deposits. It delivers the functionality of automation, and analytical mine design, making it a leader in open cut mine planning solutions globally.

MineScape Open Cut provides powerful tools to rapidly create and explore design options for open cut planning. Long-term planning tools, such as strategic and feasibility studies, are complemented by tools for short-term design objectives in terrace or strip-mining situations for dragline, truck, and shovel mines. Enhanced 3D CAD combined with Rapid CAD features makes the designing process efficient and seamless.

MineScape Drill & Blast provides engineers with an interactive 3D CAD environment within which an optimum blast pattern can be quickly laid out and projected to surfaces. It utilises designs and triangulations produced by other MineScape apps to keep a single source of truth as well as to achieve that rapid design process. Hole layout reports can be exported to GPSequipped drill rigs.

MineScape Dragline allows engineers to define and test dragline excavation methods on real pit models, quickly and efficiently. It includes functions to simulate and measure a wide variety of material movement methods including cast blasting and production dozing. These functions allow operations in the pit to be faithfully modelled. MineScape Dragline is the best tool for dig optimization to test new excavation methods quickly against real data.

MineScape Haulage Roads enables the design of mining roads along any surface. Cut and fills are generated as required while maintaining grade, curve, and specifications. Cross- sections and volumes are generated to allow the optimization of road placement and estimation of construction costs.