Mining

Operations

Software

Datamine’s wide range of operational solutions ensures you have access to practical and efficient products that meet your specific needs. From digital shift allocation, open pit and underground drill and blast, to critical ore control and dilution modelling, Datamine has the most comprehensive and sophisticated suite of solutions for your operational needs.

Exclusively designed for the needs of mine surveyors

Studio Survey is a software solution exclusively designed for the needs of Mine Surveyors. It is not a module inside a complex product but is a dedicated mine surveying product that simplifies and streamlines the processing of everyday survey tasks in mining operations of any commodity with the use of dedicated and automated reporting functionality. If increased efficiency is your biggest goal, then Studio Survey will surely be your biggest asset.

Taking you drone photos and generating textured wireframes and point clouds. Reducing the products needed on your operation.

Automated reporting functionality for extraction, compliance, stockpiles, blasting and blasted stocks.

Allowing you to spend less time in front of your PC.

A multi-user system that covers the whole process of drilling and blasting.

DataBlast is a multi-user system covering the entire open pit drill and blast process from design to in-field operations. Electronically transfer data, respond to changes in real-time, and generate reconciliation reports. Identify trends and improve blasting performance over time. Effectively design and implement your blasting plans to achieve consistent high-quality results every time.

Design environment focused on the drill and blast workflow. Manage your operation with DataBlast’s multiple data input capabilities, designed to speed up data management.

Dramatically increase operational efficiency by consolidating drill and blast data. Easily generate re-drill holes based on latest data, print customised plans and checklists.

A fully integrated tablet application, BlastPad allows for easy capture of QAQC and Charging data.

Charge requirements are automatically updated with drill and QA/QC data, providing incredible levels of accuracy for charging designs.

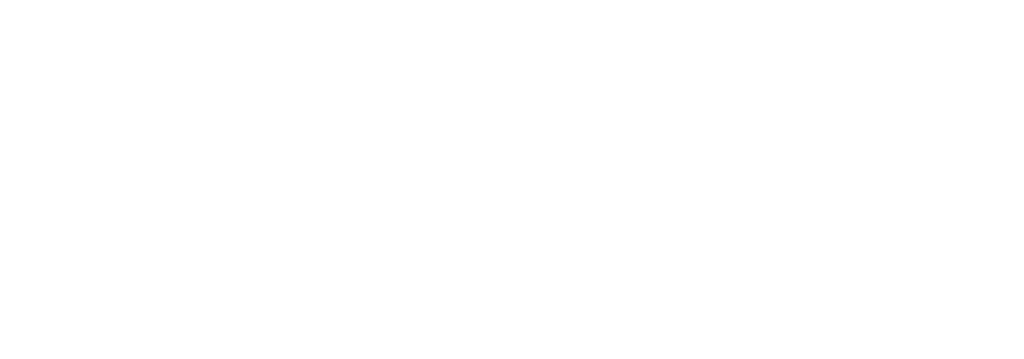

Intelligent ore control system

Regardless of the commodity that your business is in, each load of ore could be worth over $10,000. It is critical that each truck goes to the right place. Your grade control system provides the last opportunity to decide what happens to the material being loaded, and therefore must use sophisticated techniques to get the best result. Ore Controller is an intelligent ore control system that fits seamlessly into your mine’s existing operations and processes. Using a central database and customisable workflow, Ore Controller breaks up grade control tasks into clearly-defined activities, and guides each user through their day-to-day work. Implemented stand-alone or in combination with a blast movement monitoring system, Ore Controller can deliver tens of millions of dollars annually to your mine’s bottom line.

Pre-defined workflows within a comprehensive, user-friendly platform that guides users through their workflow.

Allow multiple users to collaborate on day-to-day grade control tasks, eliminating potential doubling up of tasks.

Defined and standardised work flows guarantee that grade control procedures are carried out in the same way regardless of the user.

Leverage Data in Real Time to Manage Operations and make better decisions.

Exceeding productivity targets without increasing costs is hard work. New technology innovations make it easier for miners to boost productivity by identifying root causes of key issues and eliminating them with relative ease. Addressing issues from the top of the value chain — from drilling and blasting through loading and hauling — can add up to more compliant payloads and lower cost-per-ton.

Minetrack works by installing a device in each piece of equipment that collects and sends critical information, such as: location, status, operator, and loading in real time. This information is transmitted to the control center via a proprietary communication network that covers the entire mine area. The entire mine fleet and production can be monitored in real time from the control center, using clear and tailored dashboards targeted for different operations tasks. Built by experience mining engineers for real mining operations. It’s all about how to optimize your mine performance, reduce costs, improve safety, and comply with environmental standards with the least cost and high value outcome.

Manage your assets and mine operations with efficiency and accuracy.

HOW DOES IT WORK?

Minetrack is designed to optimize operations from the shortest haul cycle to the longest value chain. With our technology, see all your mine’s data from a bird’s-eye view in the control center or dive deep into the details to make the critical changes that maximize the effectiveness of your fleet, in real-time. Master your fleet through situational awareness, optimizing haulage and blending, and live communications. Get the right information at the right time to better use equipment, improve workflows, reduce costs, improve safety, and raise productivity.

Maximize the equipment utilization in real-time, increasing efficiency and productivity of assets.

HOW DOES IT WORK?

With a real-time data stream and historical collections of individual Asset attributes, it’s easy to create visibility of status and performance of each asset to support more effective fuel management, maintenance, and performance. Highlight variances across the fleet and enable better decisions that will reduce costs, improve safety, and support compliance activities.

Track and monitor hours, operators, and drilling plans for drilling and probing equipment with real-time feedback and historical reports on equipment performance.

HOW DOES IT WORK?

Data from the control center is presented in a user-friendly interface detailing the status of each asset, the progress of each drilling plan, and the performance of each operator. Reliable data combined with checklists aligned to operations create real-time relevant information for shift operators allowing them to update scenarios as it happens. The ability to match plans to completed loads and update the status of each hole, location, or load of rigs.

Add Telemetric data to Fleet Logistics to control productive and effective hours with a new level of visibility.

HOW DOES IT WORK?

Through the integration with a proprietary telemetric data collector, Minetrack makes it possible to automate the allocation of work orders, as well as the real-time monitoring of services, providing management by vacancy, cost center, equipment, operator and other levels of control.

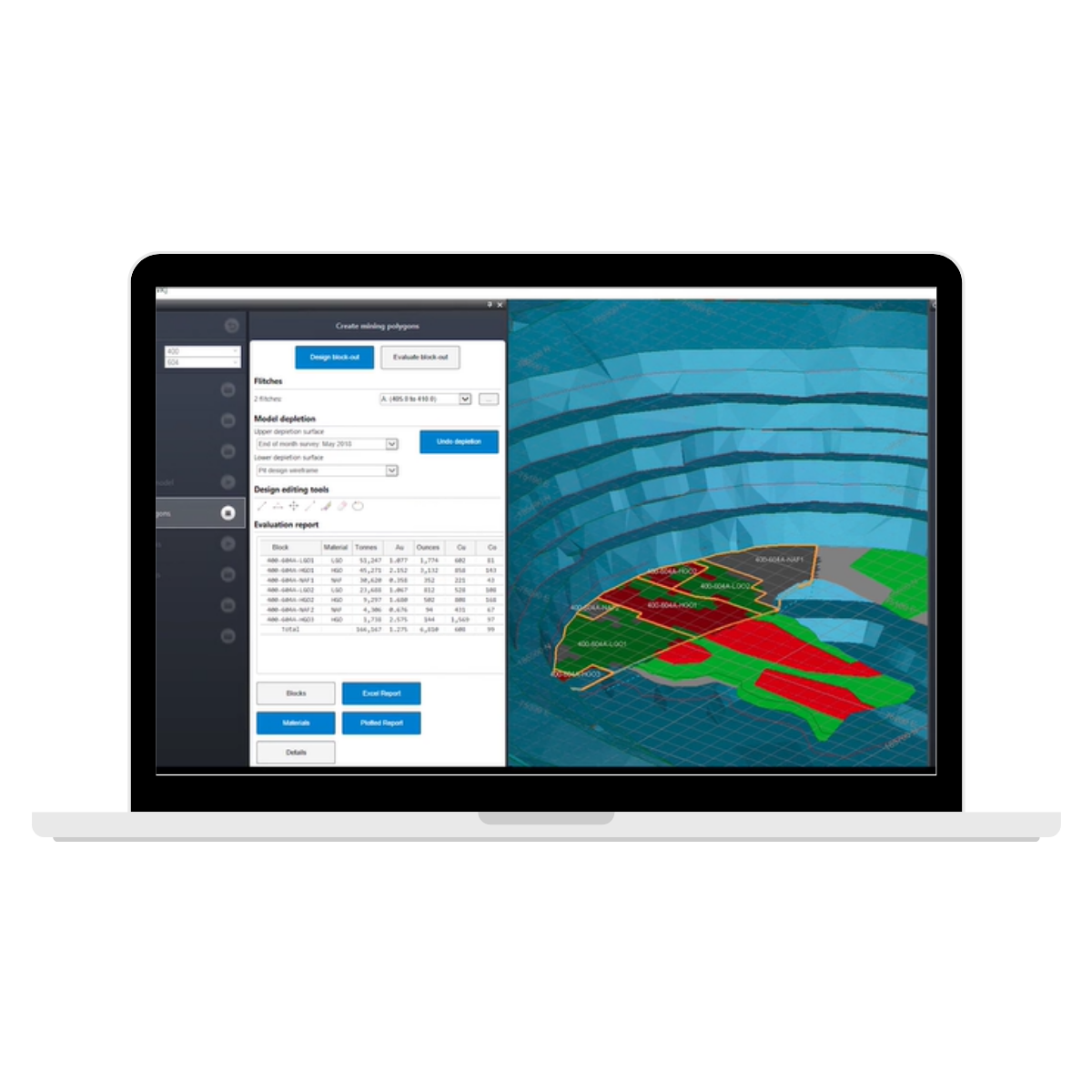

Complete metallurgical accounting solution

Production Accounting provides a complete metallurgical accounting solution designed for mining, mineral processing, smelting, and refining operations. Production Accounting addresses key production accounting challenges by providing fully auditable data entry, calculations, and approvals. It offers full integration capability for production data from various sources. It also provides the flexibility to cater to diverse site and business requirements, while enabling a corporation to use a single solution across its operations.

Adherence to best practise methods and regulations guarantees a robust metal accounting system.

Save time and minimise errors from manual data entry processes with full integration capability with data sources such as CCLAS and data historians.

Complete auditability of data entered and changed by a user, as well as in depth calculation tracing and tracking of approval of data.

Customisable authorisation process to ensure data is approved before being released for reporting.

Data management for mine labs

AssayNet LIMS contains all the features you would expect in an industrial-strength LIMS. From sample reception, logging and preparation through analysis and reporting, the program has been designed to work the way you do. Its intuitive, menu-driven interface is easy to learn, yet feature rich, providing access to a complete QC program, quotations and invoicing, stock levels and inventories, sample storage and more.

- Avoid mix-ups with Samples and / or results.

- Keeps track of every event performed.

- Data communication to all the different databases in the mine – Geological modeling, plant process control, Environmental Monitoring.

- Better accessibility to data, i.e. easy extraction of data sets, for geology, exploration, plant, etc.

- Rapid extraction of large datasets, for statistical or other analysis.

- Data communication to all the different databases in the mine – Geological modeling, plant process control, Environmental Monitoring.

- Allow better utilization of staff by reducing the amount of time spent keying in data or calculating results.

- Better time around time by automated reporting and exporting.

- Improve turnaround time.

- Integrates quality control to the entire analytical process, from sample prep, digestions, to final results.

- Data validation – Pass or Fail following the QC program in place.

- A valuable tool to gain and maintain accreditation.

- Compliance with international standards to comply with the stock markets.

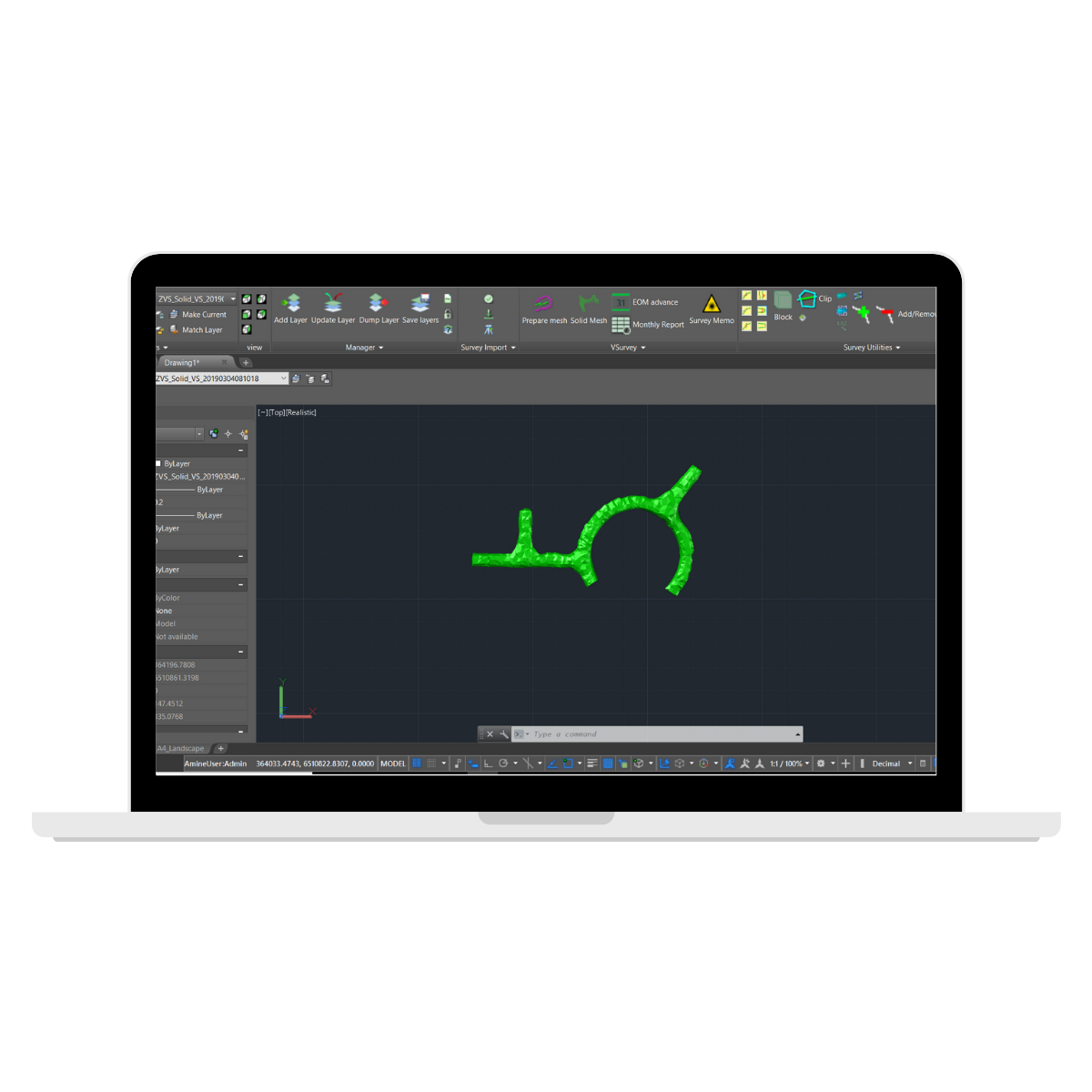

The digital planning revolution

The most advanced AutoCAD-based mine design software – Amine is the perfect tool for all underground mine surveyors. It includes a comprehensive suite of underground surveying tools including mining instruction function, automated CMS solids and underground monthly reporting summary. It simplifies and streamlines daily survey tasks whilst providing a more efficient and time-saving EOM reporting process. Amine can deliver automated workflows that align with your company’s current processes and needs, with the integrated ability to be fully customisable for each individual. It is flexible enough to be used for any commodity, ore body and mining method, whilst being intuitive enough for you to easily learn and adopt.

maintaining data structure and security.

Dedicated process to complete your End of Month report.

Monitor your compliance to design with cut by cut overbreak and underbreak.

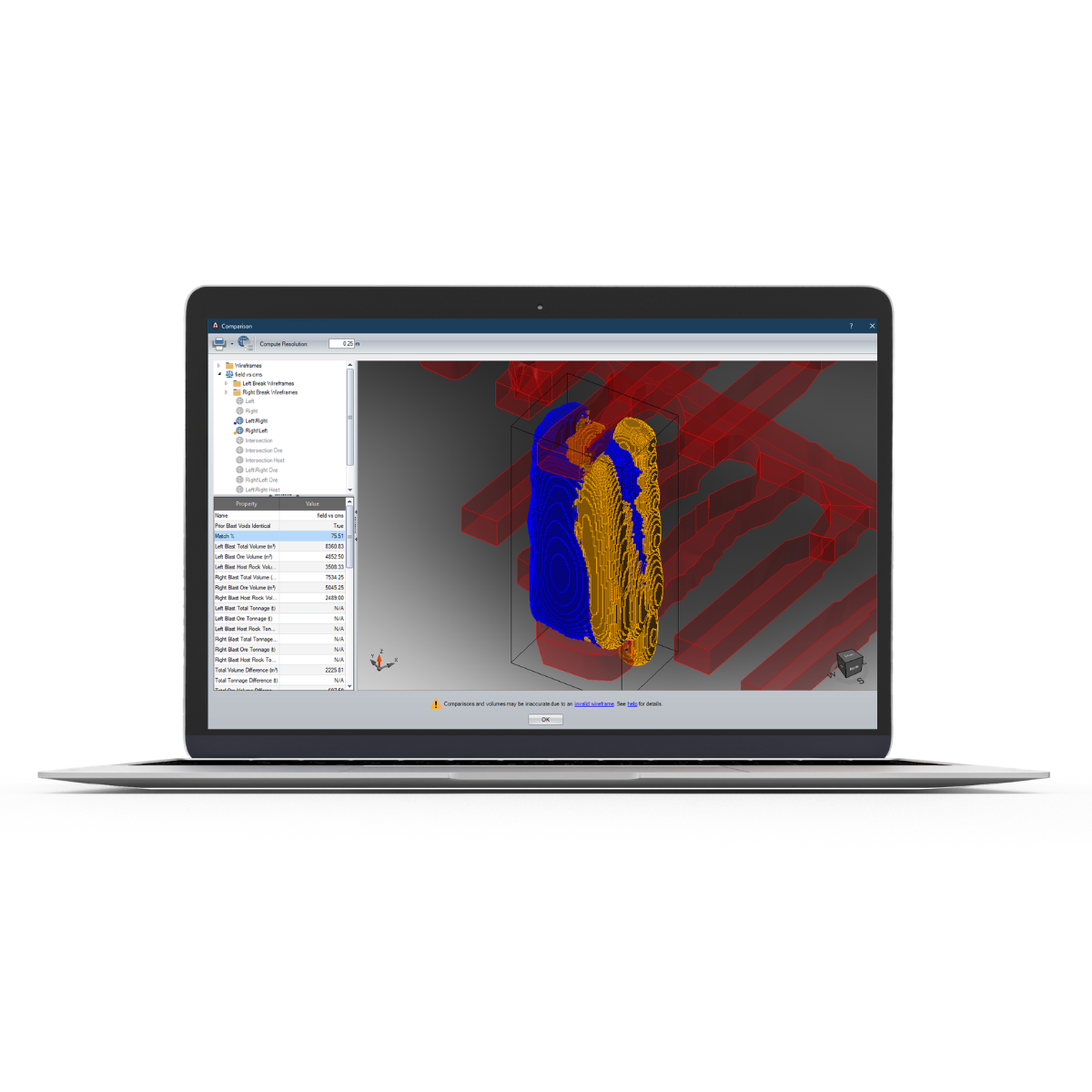

Multi-Faceted UG Drill & Blast Solution

The ultimate solution for providing interactive and automated underground drill and blast design. AEGIS has a multi-faceted system, allowing users to rapidly compare different scenarios and generate ring layouts, charging plans, and blast designs to paper or directly to compatible drill rigs using IREDES. Our break model can determine an optimal blast pattern suitable for the rock and explosive properties that can generate fragmentation suitable for the haulage equipment reducing costs. These solutions can automatically lay out your entire stope in seconds while being incredibly flexible, allowing easy design adjustments – a few rings, individual holes or charges. Additionally, the AEGIS Drop Raise Editor allows slot raises to be designed, sequenced, and inserted into the drilling plan.

AEGIS Designer automatically generates all drill holes for a stope rapidly and accurately, with minimal user input. A layout is automatically generated in seconds by simply defining existing voids, geological contacts, optional stope design, and setting the burden and toe spacing. Unlike traditional underground blasting software, which requires users to start from scratch when adjusting burden or spacing, AEGIS Designer instantly generates the layout using new values, saving time and providing added flexibility in design. This solution allows for the simultaneous design of rings in four views – plan, section, longitudinal and 3D – ensuring no important details are missed.

- Fast & Repeatable

Automated processes guided by user input parameters deliver consistent designs to site standards. - Compare Scenarios

Quickly generate different ring layouts and charging patterns. - Completely Integrated Solution

Seamlessly connected data sources with Studio UG mine planning software and a common engine for geological evaluation.

The AEGIS Analyser is a powerful tool providing advanced blast simulation and modelling capabilities for underground engineers – essential for optimizing blasting operations.

It features a wide range of capabilities, including break limit predictions and blast dilution analysis. Engineers can use the break model to determine the optimal pattern dimensions suitable for ground conditions and explosives. The break model will show the break overlap and the shockwave interaction with the free face. An optimal pattern can generate suitable fragmentation for the haulage equipment and reduce overbreak and associated costs. The analyzer provides the Advanced Cost model allowing a thorough and detailed cost analysis of stope, making it possible to compare different pattern variations or different explosives on a level playing field. Combining the cost model with the break allows for explosives comparisons in your mine and understanding true costs.

The CMS field fit can predict the shape of the adjacent break volumes based on the laser scans of previous blasts. This tool can generate the potential void shapes of subsequent blasting and can be used to calibrate the rock properties linking the observed results with the model.

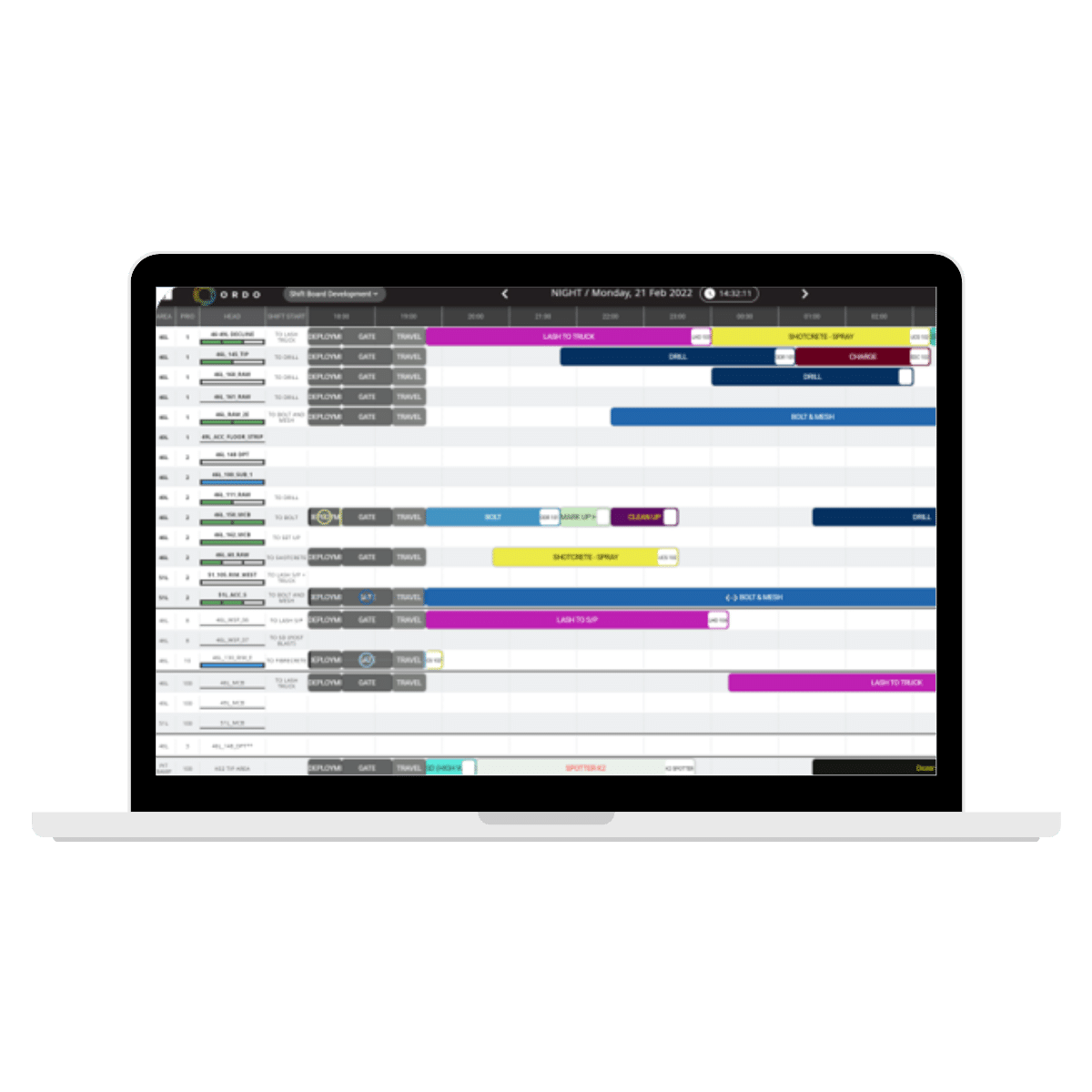

Next-generation shift deployment planning for intelligent mining

ORDO® is supervisor centric software that modernises traditional shift planning processes, facilitates the navigation of complex planning interactions, motivates supervisors to develop improved planning outcomes and engages the workforce through plan visualisation. Intuitive, touchscreen design supports easy adoption across all digital skill sets. Built for true customisation of user-defined functionality, nomenclature and workflows, ORDO® can support shift planning applications across many industries.

ORDO® is a robust tool that stabilises and de-risks shift planning - regardless of external factors. ORDO® provides improved plan quality and visibility as well as

seamless workforce engagement with plans.

While ORDO® motivates the supervisors to focus on getting the best shift plan, not just any shift plan, it also provides greatly enhanced regulatory compliance outcomes.

Digitalise all shift plans and task allocations for retrieval at any time for analysis and reporting.

ORDO® ensures all tasks are planned, resourced and communicated consistently, ensuring the workforce clearly understands work requirements. Plan transparency allows the workforce to provide feedback which supervisors can easily incorporate into the plan in real time. Providing consistency around shift planning and deployment, ORDO® helps define and articulate “the way we do things around here”.

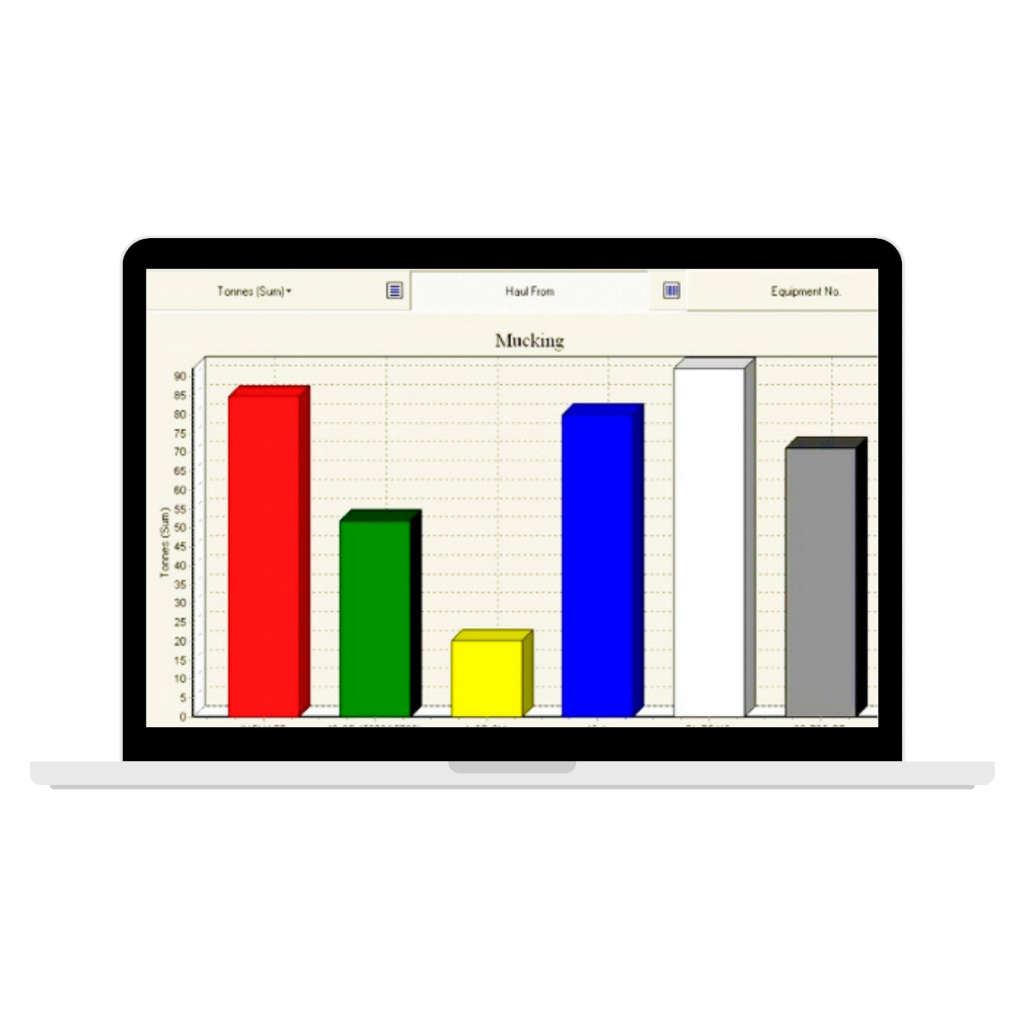

Customisable data entry & reporting system

SIMS is an intelligent data and reporting centralisation system that eliminates the need for paper logs. With a secure database that is configured specifically for the mining industry needs, it allows you to collect information, produce accurate real-time reports and centralise all mine production information.

A one-of-a-kind centralised data entry and reporting system specifically designed for the mining industry needs.

Increased team efficiency with seamless data sharing between all departments.

All departments can easily collect information without the need for paper logs to produce accurate real time reports.

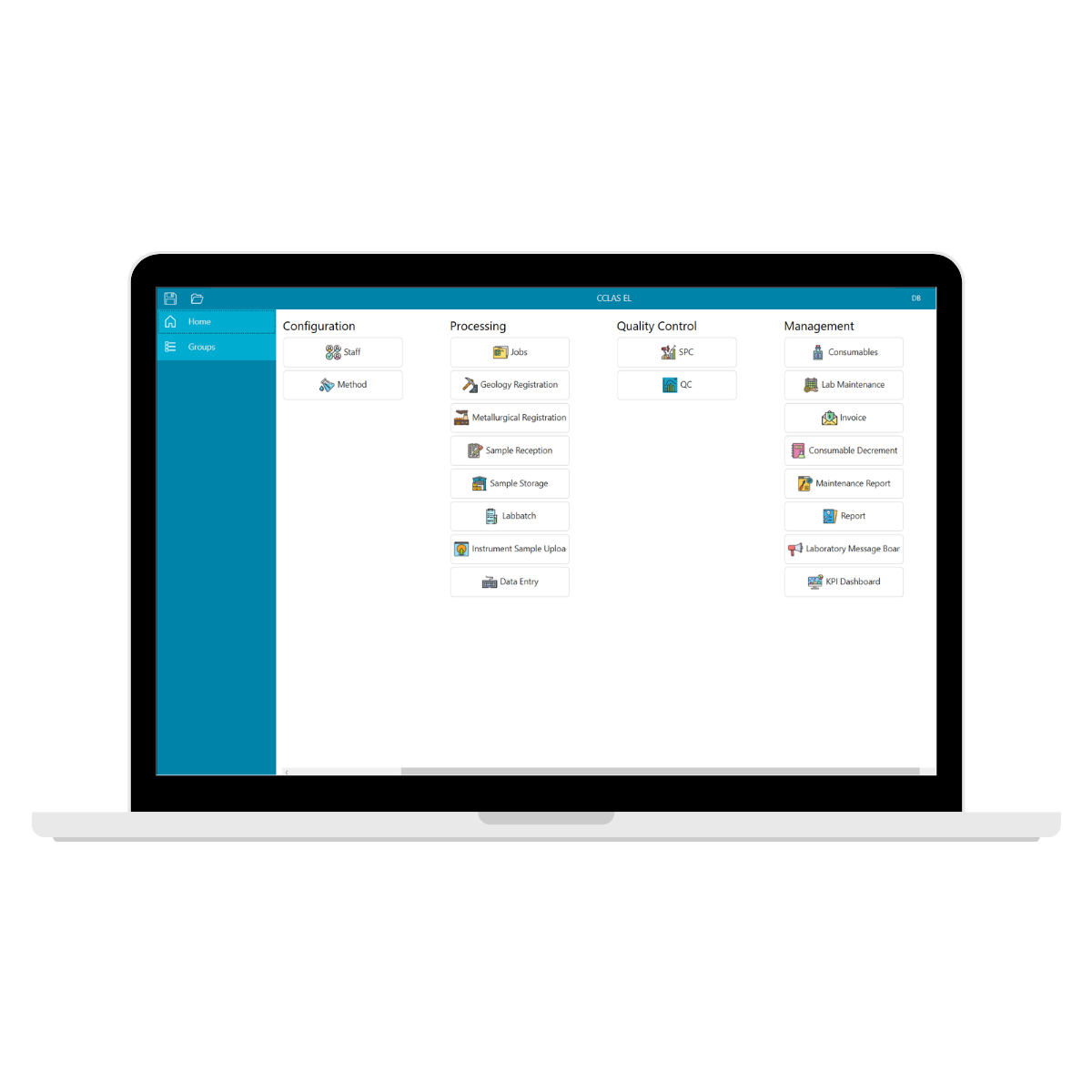

Quality results you can trust

CCLAS helps laboratories manage their samples and data more efficiently by automatically registering samples, printing barcode labels, capturing weights from balances, integrating with instruments, performing automatic calculations, creating reports and invoices and integrating with external systems. While having full auditability across the system.

Allows production samples to be automatically registered along with printing of barcode labels.

Two-way integration with instruments, minimizes wasted time that your technicians spend manually transposing data.

Automatic reporting of QC performance, helps your chemists save time.

Established integration with current Datamine software along with robotic systems and industry standard plant systems and ERPs.

Our aim is to support your company to improve the quality of your analysis, increase productivity and lower the costs of your laboratory.

Datamine’s laboratory advisory and consulting services include:

- Laboratory audits

- Advice on building a new laboratory

- Help commissioning new instruments

- Investigation of laboratory procedures