One of the topics I never really understood well at school was the concept of pushbacks (also known as phases or cutbacks) in open-pit mining. Time and again we were shown a big pit design (the final pit) that was then split into smaller phases (pushbacks) and personally, I failed to fully grasp the reason behind that. I had a couple of theories about why I thought this happened. The most convincing was the Pizza theory – I knew that pizza is more manageable when cut into slices and maybe that is why the big pit is always cut into smaller phases – to make things more manageable. Well, would you believe me if I told you that it literally took 3 minutes from this other brilliant chap at work to explain to me what pushbacks are and why they are crucial in open pit mining? Things have never been soo clearer.

Pushbacks can be simply defined as a series of manageable phases (yes, my pizza theory was almost there) that can be exploited with the available mining equipment and that can meet practical geotechnical and operational mining constraints. Pushbacks play a very crucial role in open pit mine design and optimisation. Production scheduling is based on the underlying set of pushbacks, so the manner and approach in which pushbacks are selected, designed, and scheduled have a remarkable impact mainly on the mine’s profitability.

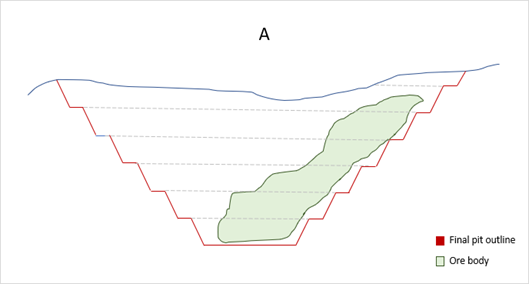

I am going to demonstrate the importance of pushbacks using the simple illustration below and I hope my explanation is as clear as day.

Open pit mines are exploited bench-by-bench from the top bench, all the way to the bottom of the pit. There is no way out of it. Diagram A below represents a big final pit (coloured in red) that has no pushbacks. As mentioned above, exploitation of open pits involves completely mining the upper bench in the pit before moving to the bench below. Mining this huge pit with no pushbacks represents the “worst case” scenario since it gives the lowest Net Present Value (NPV) for the pit. In the upper benches of the pit, you need to mine a lot of waste before you can hit any significant amounts of ore.

You might be tempted to think that there is no problem with mining too much waste because you will eventually expose a lot of ore and you will be swimming in a lot of money then. The Net Present Value being a function of time disagrees with you. Mining significant amounts of ore later on in the Life of Mine actually destroys your NPV. The big pit with no pushbacks also represents a scenario with a big financial risk. Firstly, you will need a lot of capital for waste mining in this scenario. Secondly, with mining, you are always exposed to the risks associated with external, global factors such as commodity prices, exchange rates, etc. In this scenario, you make a commitment to mine a very big pit and considering that it may take you a while before you get to the ore, any significant, bad economic change would definitely kill your operation.

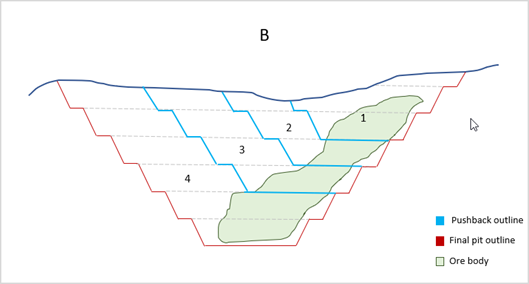

The problem presented by Diagram A can usually be mitigated by introducing pushbacks. Now let us look at Diagram B below which represents the final pit (still coloured in red) being cut into 4 pushbacks (coloured in light blue). Keeping in mind that we are still mining bench-by-bench from the top, it is clear that Diagram B has a relatively smaller amount of waste to mine in pushback 1 before hitting significant amounts of ore. This represents the “best case” scenario since it generates a better NPV due to earlier access to significant amounts of ore. Once you hit good amounts of ore in pushback 1, you can start stripping pushback 2 to ensure that you do not mine yourself into a corner and there is always continuous ore supply to the plant.

A good set of pushbacks helps you manage the financial risks that are associated with external global factors – well at least better than a pit with no pushbacks. Here is an interesting notion to consider regarding the management of risks in mining. The pushback that you are exploiting today (e.g., pushback 1) is your final pit until such a time that you decide to strip the next pushback (e.g., pushback 2). Before committing to the next pushback, the norm is to run your Life of Mine plan again based on the most recent and better-forecasted engineering and economic parameters. So should the parameters (like prices etc.) be extremely bad, you would have only committed to mining a pushback instead of the entire final pit and chances are you could still make money in that pushback because you would have less waste to worry about.

Now the golden question is what is considered to be a good pushback?

Any pushback that you generate must first be able to address the following critical points:

- Geotechnical variables – the overall slope angle must be respected to ensure the safety of the pushback. Note that in some rare cases, it is possible for pushbacks to have a slightly steeper slope angle compared to the overall slope angle of the final pit. This is usually done for pushbacks with a shorter life span to reduce the amount of waste inside the pushback with adjusted walls. This is definitely a topic for another day!!!

- Quality and size constraints – quality and size constraints include things such as the desired amount of material (ore and waste) inside the pushback, the extraction rates to meet the production targets, and the size and type of mining equipment – which eventually determines the minimum operational width of the benches in the pushback.

So, how big should the pushback be?

The selection of pushback width has numerous critical consequences on the NPV and the operation of the mine. Pushbacks that operate on the minimum width may reduce the required stripping and help you reach the ore quickly. However, narrow pushbacks provide little flexibility to the operation and as such may result in relatively higher operating costs. On the other hand, wider pushbacks provide flexibility in the operation. Generally speaking, blasting efficiencies and productivity are relatively higher in wider pushbacks. Wider pushbacks can also support better cycle times since you afford to have wider access for both truck fleets as well as ancillary fleets. But as you can imagine, wider pushbacks may require a significant amount of stripping, and large capital investments and may destroy the NPV due to the time it takes to reach the ore. So yes, there is a sweet spot between the narrow and wider pushbacks, and pushback optimisation tools such as Datamine’s Studio NPVS can help you optimise the size and location of your pushbacks as well.

Once you have addressed the geotechnical conditions as well as the quality and size constraints, then the next step is to find a set of practical pushbacks that will help you produce superior schedules and consequently maximise the NPV of your project. This is usually achieved through scenario testing using optimisation software such Datamine’s Studio NPVS.

Written by:

Thabang Maepa

Solution Lead – Open Pit Planning

Datamine Africa

Contact us for more information.